- HOME

- PRODUCTS

- STAINLESS STEEL

- CARBON & ALLOY STEEL

- SPECIAL ALLOYS

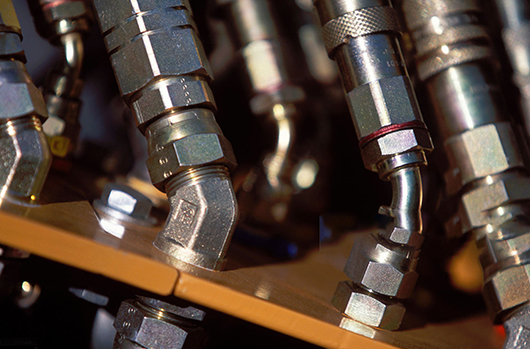

- Buttweld Fittings

- Forged Fittings

- Flanges

- Pipes & Tubes

- Sheets & Plates

- PH GRADES

- ABOUT US

- INDUSTRY

- CERTIFICATION

- OUR CAPABILITIES

- CONTACT US

HK Steel Corporation is a leading Manufacturer & Suppliers of High Nickel Alloys Like Hastelloy, Inconel, Monel, Nickel Copper alloys, Titanium, Cobalt alloys, Duplex, Stainless Steel and other Nickel based alloys in the form of Round Bars, Plate, Sheet, Strip, Wire, Pipe, Pipe fittings and flanges.

© 2023 H.K. Steel Corporation. All Rights Reserved.